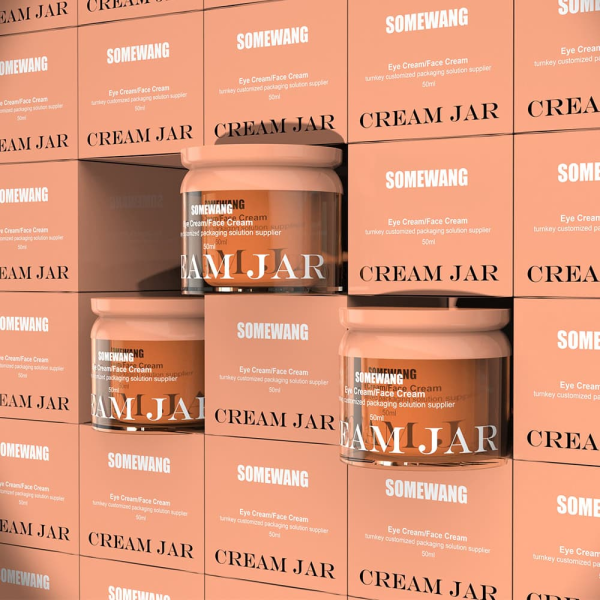

China, 19th Aug 2025, – Somewang, a global provider of manufacturing and R&D-led packaging solutions, has broadened its premium cosmetic packaging. The expansion strengthens the capabilities to suit the needs of world-class beauty brands as they evolve and innovate. The premium cosmetic package expansion is designed to aid brands in convincing consumers through novel, sustainable, high-quality packaging to honour their customers’ various market desires.

With the expansion comes concrete design options as well as enhanced material testing protocols and increased customisation potential. The expansion builds on the company’s many years of expertise in the market by enhancing the advertised bottles, jars, tubes, pumps, sprayers, and closures, and reflects a focus on stronger product development with international partners.

“This expansion of the premium cosmetic packages exemplifies the dedication to the world-class cosmetic brands through the packaging supply and offering consumers,” said Steven Wang, Chief Executive Officer of Somewang. “This broadening of capabilities means the world-class brands will be set up to obtain packaging that is as unique and distinctive as the products contained inside it.”

Alongside increasing its manufacturing abilities, Somewang has added R&D resources to get products processed faster. The company’s zero-risk quality assurance plan, which includes material and graphic quality testing, along with testing in accordance with ASHA/QSR standards on raw materials.

The company is also capitalizing on the increased demand for more environmentally sustainable options in cosmetics. As beauty brands continue to integrate more sustainability into all facets of their manufacturing and distribution, packaging manufacturers are being asked to provide environmentally responsible alternatives as well as sustainable options that aesthetically match their previous packaging styles and are tough enough for real-world applications. Somewang’s additional product options consider all of those requests through recyclable materials, more intelligently used manufacturing processes, and modular design systems that allow for less waste during building and transporting.

Somewang’s position in the market is supported by its integrated OEM and ODM services, which enable clients to collaborate closely during the concept, prototyping, and production stages. This end-to-end approach ensures that packaging solutions can be tailored to brand identity, functionality requirements, and regulatory compliance across multiple regions.

Industry experts have suggested that with the growth of emerging beauty trends, new distribution channels via e-commerce, and more options for consumer-tailored products, the global cosmetic packaging market will continue to grow steadily. Against this backdrop, Somewang’s expansion is designed to give international brands a reliable partner capable of adapting to shifting demands while maintaining consistent quality.

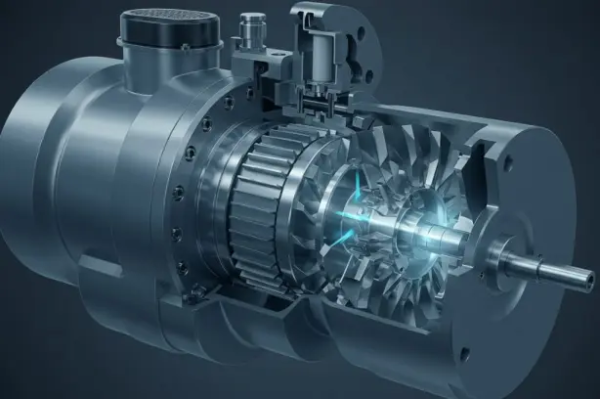

Looking ahead, the company plans to leverage advancements in material science and manufacturing technology to further refine its packaging solutions. This will include the exploration of bio-based polymers, the integration of smart packaging elements, and the development of lighter-weight formats that reduce environmental impact without compromising performance.

Steven Wang added, “The next phase of development will be guided by a focus on sustainability, adaptability, and innovation. By investing in emerging technologies and forward-thinking design, the company intends to remain a trusted partner to brands navigating the changing landscape of cosmetic packaging.”

Somewang’s continued expansion will improve its ability to establish partnerships around the world to produce packaging solutions that deliver on both creativity and practicality. The company values establishing collaborative partnerships and believes that through working together with clients, the complex problems of packaging in beauty and cosmetics can be addressed.

For media inquiries regarding Somewang’s cosmetic packaging solutions, please contact Somewang at +86 574 8825 1730 or via email at pr@somewang.com.

Media Contact

Organization: Somewang

Contact

Person: Steven Wang

Email:

pr@somewang.com

Contact Number: 8657488251730

Country:China

The post

Somewang Expands Premium Cosmetic Packaging Solutions for Global Brands appeared first on

Brand News 24.

It is provided by a third-party content

provider. Brand News 24 makes no

warranties or representations in connection with it.